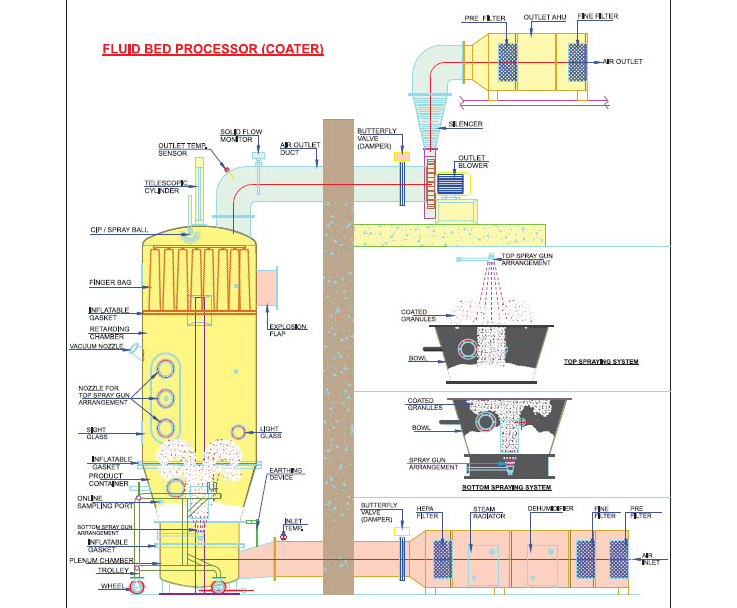

FLUID BED PROCESSOR

Fluid bed process work on the principle of fluidization in which hot gas or air is introduced into the spaces between solid particles. Upward forces on the particles increase as the air's velocity increases causing them to equal the gravitational forces below.

SALIENT FEATURES

- Cartridge filter system for continuous process made of SS 316. Easily removable for cleaning purpose.

- All process parameters are interlocked, thus no possibility of batch failure.

- Online sampling arrangement.

- Unique spray gun for chokeless and uniform spray.

SPECIALISATION

- Top flexibility.

- Simple to convert in just minutes.

- Flexible thanks to modular design.

- Drying, granulating and coating in a single device.

- Fully automatic with scada plc control